Hard facing capabilities

Available Hard facing (Welding) processes are

- LASER CLADDING

- PTA Welding Equipments

- Horizontal TIG Welding Equipment

- 600 Amps TIG welding Equipments

LASER CLADDING & HARDENING PROCESSES:

Laser cladding process utilizes a laser source to create a melt pool of the base material and cladding material is introduced into this melt pool in powder form. The energy of the laser melts the cladding material also to form alloying zone between base material and clad material resulting to a metallurgical bonding with good control on required dilution rates.

Laser hardening process is environmental friendly process which will produce very effective hardening layer compare to conventional hardening processes.

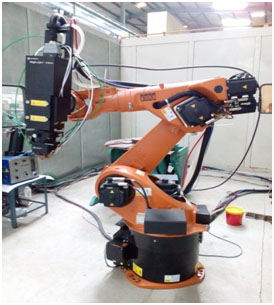

Laser cladding & Hardening Facility at SSCT:

ADVANTAGES OF LASER CLADDING PROCESS:

1. Lower dilution levels

2. Metallurgical Bond

3. Minimal heat effected Zone

4. Minimal part distortion

5. Reduced post processing

6. Highly repeatable process

ADVANTAGES OF LASER HARDENING PROCESS:

1. Very low distortion

2. No quenching requirements

3. High process rates

4. Easy case controllability

5. High process flexibility

6. Automation possible

7. No requirements of absorbent coatings

PTA PROCESS

The main advantage of PTA Welding process is low dilution levels than TIG & MIG welding processes.

Process Description

In PTA welding, two DC power supplies are used to first establish a pilot arc (non-transferred arc) between the tungsten electrode and the anodic nozzle and then a transferred arc between the tungsten electrode and the workpiece. The pilot arc is struck by an High Frequency device and the plasma gas flowing around the cathode is ionized at the electrode tip. When the transferred arc is ignited, the workpiece becomes part of the electrical circuit and the plasma arc is directed and focused through the torch orifice into the workpiece. Powder is metered, under a positive pressure of Argon flow, from the bottom of the torch into a pool of molten metal on the workpiece surface.

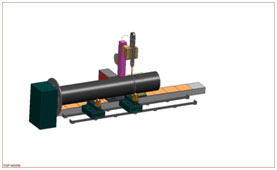

HORIZONTAL TIG WELDING EQUIPMENT

This Equipment very useful for carrying narrow groove welding to join thick sleeves, long tubes and to carry cladding on large components. The welding principle of this equipment is Tungsten Inert Gas Welding (TIG) principle.

1

1 2

2 3

3 4

4 5

5